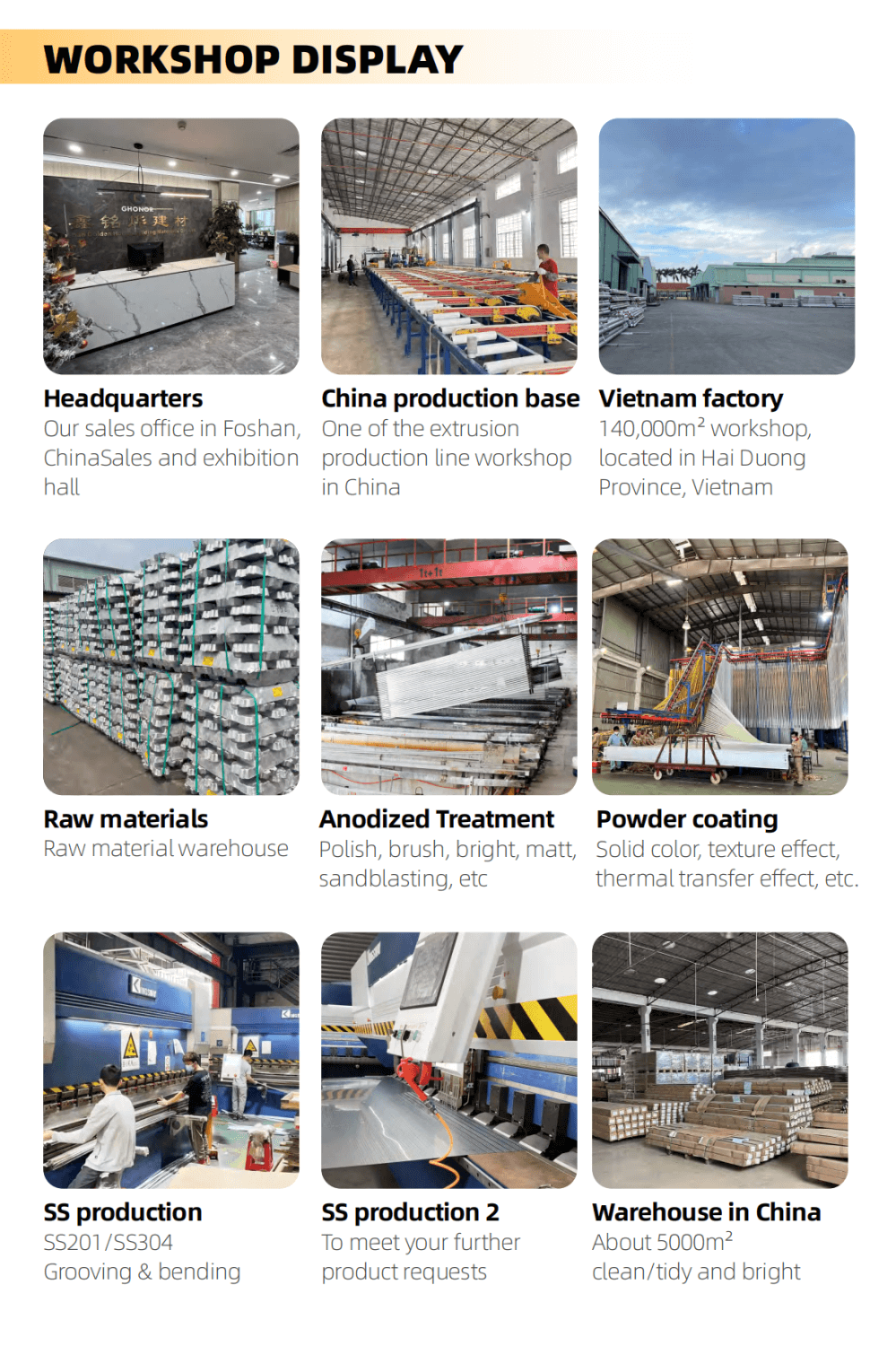

For providing an anti-dumping solution, we set up a production base in Vietnam to provide tile trim, fence, and metal plate hardware in aluminum and steel for buildings.

In order to make up for the shortcoming of Vietnam's weak supply chain, we decided to invest in a brand new modern automated anodizing production line.

Now the first automated anodizing production line in northern Vietnam has started construction in our Ghonor Vietnam factory.

We will continue to update the assembly situation of the anodizing production line, and it is expected to be put into production next month.

Vietnamese laws and policies may impose restrictions on foreign investors and companies, such as foreign investment regulations, trade agreements, and environmental protection regulations. Therefore, building an anodizing plant in Vietnam may require meeting certain legal and policy requirements, as well as obtaining the necessary licenses and approvals.

2: Market Demand

Building an anodizing plant in Vietnam requires considering market demand, including product and service demand, as well as local and international competition. Insufficient market demand or intense competition could increase the difficulty of building an anodizing plant.

3: Resources and Supply Chain

Building an anodizing plant requires considering the supply chain of raw materials and equipment, as well as the local labor market and transportation infrastructure. If local resources and supply chains are insufficient or transportation infrastructure is not well developed, the difficulty of building an anodizing plant will increase.

4: Technology and Talent

Building an anodizing plant requires relevant expertise and knowledge, as well as experienced personnel to operate and maintain the equipment. A lack of relevant technology and talent in the local area could increase the difficulty of building an anodizing plant.

5: Environmental and Social Responsibility

Building an anodizing plant requires considering environmental and social responsibility, including the impact on the environment and local communities, as well as meeting local environmental standards and social responsibility requirements. Failure to meet these requirements could lead to criticism and legal litigation, affecting the operation and development of the plant.

Powder Coating Line In Vietnam