Aluminum alloy is made of magnesium and silicon as the main alloying elements and the original color is only a rough silvery white, this is without any surface treatment.Aluminum alloy is made of magnesium and silicon as the main alloying elements and the original color is only a rough silvery white, this is without any surface treatment.

Aluminum alloy row material

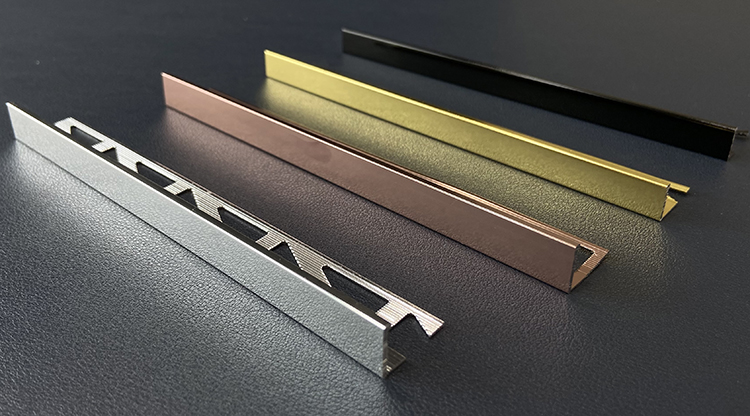

Aluminum tile trim products not only protect the corners from collision damage but also plays a very important decorative role in different architectural environments. In order to cater to various decorative styles, there are many options for the surface treatment of aluminum tile trim products.

Anodizing surface treatment is very popular for aluminum

Anodizing can not only solve the defects of aluminum surface hardness and wear resistance, but also prolong the service life of aluminum and enhance the aesthetics. It is currently the most widely used and very popular process.

Anodizing refers to the electrochemical oxidation of metals or alloys. Aluminum and its alloys form an oxide film on aluminum products under the corresponding electrolyte and specific process conditions under the action of an external current.

The production process is to clean the extruded aluminum profiles and put them into the oxidation pool filled with color seasonings, then soak, seal holes, wash with hot water, and dry to complete the product. It is characterized by a smooth, glossy surface and a strong metallic texture.

Different colors of polishing treatment

Polishing is a processing method that uses mechanical, chemical, or electrochemical methods to reduce the surface roughness of the workpiece to obtain a bright and smooth surface. After mechanical polishing and electrolytic polishing, the aluminum material can approach the mirror effect of stainless steel, giving people a sense of high-end simplicity and fashion future.

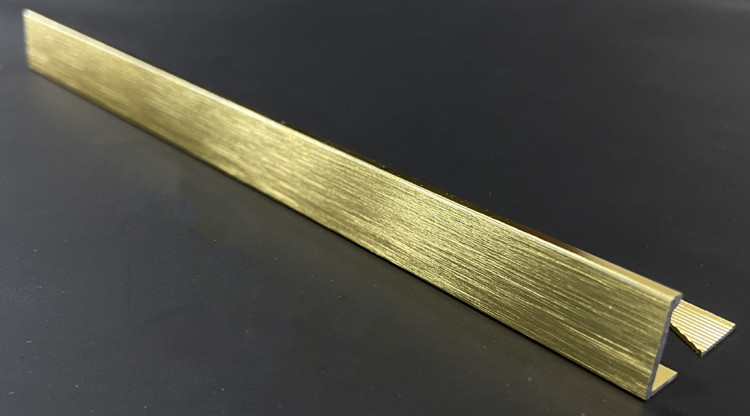

Brush gold

The production process is to get mill-finished aluminum tile trim profiles.

Brush them in an aluminum brushing machine, get different decoration lines based on different mesh brushing wheels, and make them anodized. Now the brush surface is also very popular on the market.

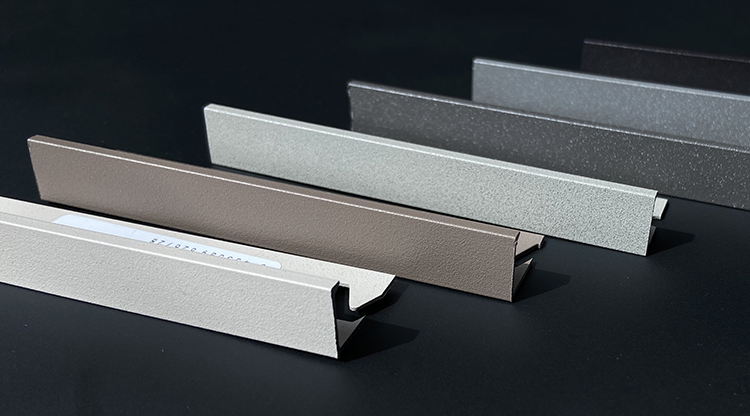

Powder coating

Our powder coating workshop

Powder coating is coloring by brushing particle seasoning, also known as electrostatic coating, which is based on the physical phenomenon of electrophoresis so that the atomized paint particles are negatively charged on the high-voltage electric field, and under the action of the electrostatic field, directed flow to the positively charged surface of the profile, thereby adhering to form a firm film.

Color can be customized more cause of the equipment process and operability with powder coating are stronger.

Wood grain transfer treatment for aluminum profiles

First paste a layer of porous film with a wood grain transfer pattern on the surface of the qualified aluminum material after powder electrostatic coating, and then vacuum to completely cover the porous film on the surface of the profile, and transfer the ink permeated on the film by heating, penetrates the powder coat for a wood grain look.

So, what kind of surface treatment do you prefer for aluminum profiles?

Find us, and get the free samples.